- Whatsapp: +8613732201621

- Email: [email protected]

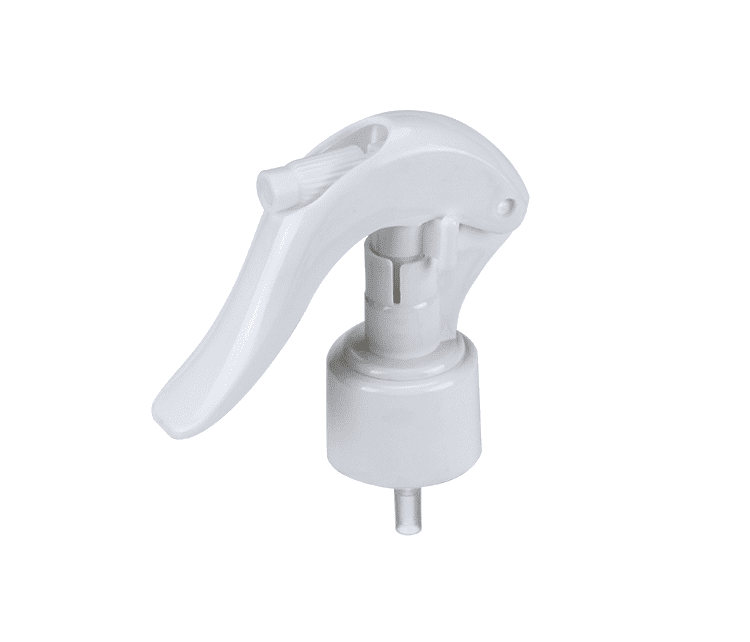

A trigger sprayer is a manually operated device that attaches to the top of a bottle, allowing the user to dispense liquid in the form of a spray, stream, or mist. Often used with plastic bottles, it’s activated by pulling a trigger, which pumps the liquid through a nozzle.

Understanding the spray bottle components is essential when choosing the right sprayer for your product. A standard trigger sprayer consists of the following spray parts:

Nozzle: Controls the spray pattern (mist, stream, or off).

Trigger: The user-operated lever that initiates pumping.

Pump Mechanism: Draws liquid from the bottle and sends it through the nozzle.

Dip Tube: A long plastic tube that reaches into the liquid and brings it to the pump.

Closure/Cap: Connects the sprayer to the bottle, typically available in various sizes to fit standard neck finishes.

Versatile Dispensing: Adjustable nozzles offer a variety of spray outputs.

Controlled Usage: Users can control the amount of product dispensed.

Ergonomic Design: Designed for ease of use and hand comfort.

Cost-Effective: Durable and refillable, reducing packaging waste.

Customizable: Available in multiple colors and styles for branding or product differentiation.

Trigger sprayers are widely used across multiple industries due to their convenience and efficiency. Below are the key application areas:

Trigger sprayers are commonly found in cleaning products, such as:

Glass cleaners

Disinfectants

Surface degreasers

Air fresheners

Their ease of use and control make them ideal for everyday household chores.

In gardening, trigger sprayers are used for:

Fertilizers

Insecticides

Herbicides

Plant mists

They provide an even distribution of liquids and help reduce product waste.

Cosmetic brands use trigger sprayers for:

Hair sprays

Body mists

Facial toners

Setting sprays

They deliver fine mist applications, enhancing the user experience.

In industrial settings, trigger sprayers are often used for:

Solvents

Degreasers

Maintenance fluids

Cleaning solutions

Durable components ensure performance even with harsh chemicals.

For vehicle care, trigger sprayers are ideal for:

Glass cleaners

Tire shines

Interior protectants

Engine degreasers

They offer targeted application, reducing overspray and waste.

In pet grooming, trigger sprayers are used for:

Deodorizers

Coat conditioners

Tick and flea treatments

Gentle misting options make them safe and comfortable for animals.

Selecting the correct trigger spray depends on several factors:

Chemical Compatibility: Ensure materials (like the dip tube or ball valve) are suitable for your liquid.

Spray Output: Choose an output rate (e.g., 0.7cc to 1.6cc) based on how much product needs to be dispensed per spray.

Nozzle Style: Decide whether you need a mist, stream, foam, or adjustable spray.

Dip Tube Length: Should be tailored to bottle size and product viscosity.

Closure Size: Make sure the sprayer fits your bottle’s neck finish.

Filling Method Compatibility: Consider whether your production line is manual or automated, which may affect sprayer choice.

Consulting with a packaging expert can also help you avoid compatibility issues and ensure optimal performance.

A trigger sprayer may seem like a simple component, but it plays a vital role in product performance, user satisfaction, and brand differentiation. By understanding its spray parts, applications, and selection criteria, you can ensure your product stands out and performs reliably. Whether you’re packaging a household cleaner or a high-end facial mist, the right trigger spray makes all the difference.

At HTX PACK, we specialize in delivering high-quality trigger spray solutions tailored to diverse industries — from household cleaning and cosmetics to industrial maintenance and agriculture. With a focus on innovation, material compatibility, and ergonomic design, our spray bottle components are trusted by brands looking for performance and reliability.

Privacy Policy | SiteMap

Copyright Hangzhou Hangtianxia Bio Tech Co.,Ltd